Equipment and Machines

RingCrown Technology

Efficient, Flexible Capping Solutions for Ring Pull bottle caps. Seamless Conversion – New Product Capability Within Hours Transform your existing crown cork capping machine into a dual-cap...

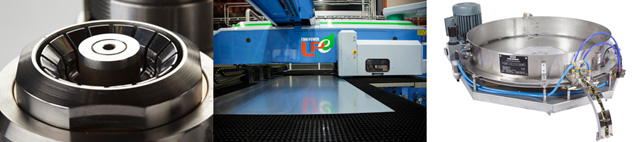

Sorting Hoppers for ring pull bottle caps

Efficient Orientation of Ring Pull Caps for Consistent High-speed Line Performance The sorting hopper is a key component of Finn-Korkki’s RingCrown Technology equipment, ensuring that each bottle...

RingCrown Sealing Heads

Compatible with All Leading Manufacturers of Crown Capping Turrets Finn-Korkki offers high-performance RingCrown sealing heads engineered to integrate seamlessly with a wide range of...

Custom-Designed Cap Chutes for ring pull Closures

Precision Cap Handling for Consistent, Efficient, High-speed Capping Efficient cap handling is a key component of any high-performing bottling line. Finn-Korkki provides bespoke cap chutes made...

Ring Pull Cap Applier

Hygienic and Reliable Cap Placement for Enhanced Product Integrity Finn-Korkki's Ring Pull Cap Applier is specifically engineered for use with all makes of ring pull bottle caps, for example...

Manual Capping Solutions for Ring Pull bottle caps and Crown Caps

Reliable, versatile ring pull cappers for low-volume production, testing and specialised applications At Finn-Korkki, we design and manufacture two robust manual single-head capping machines –...