Finn-Korkki - A sustainable partner

How we see and implement sustainability

We are Finn-Korkki, a family-owned company that produces bottle caps in Finland. Our business operations go back to 1868. We deliver products to more than 50 countries across the globe to meet our customers’ needs. For us, sustainability means an environmentally aware production making products that are food safe for the customer to use. In our operations, particular attention is given to the climate impact of our production and the logistics chain. We understand that ensuring the well-being of our employees helps to promote sustainably produced products and solutions.

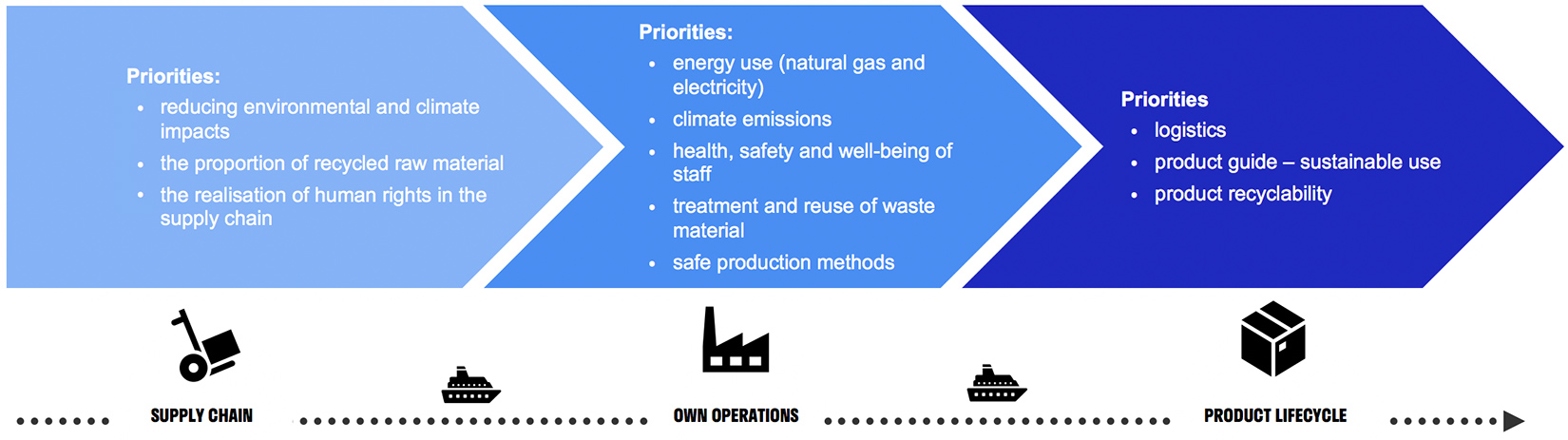

Value chain impact

Our sustainability themes

We deliver our products to more than 50 countries every year. Each consumer opens and enjoys the contents of a bottle sealed with one of our bottle caps.

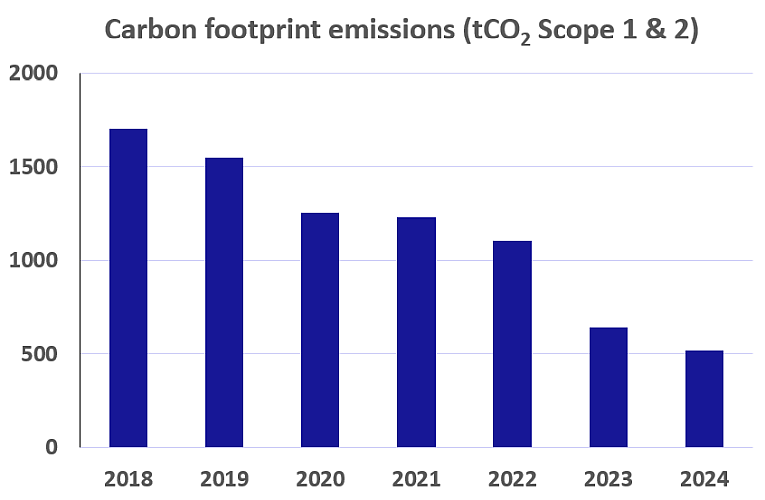

We have investigated the impacts of our own activities on the climate and the environment. The carbon footprint of our own operations is currently 520 tonnes of CO2 emissions.

Our aim and our commitment is to create a good workplace and working community for our employees.

Our operations are certified and documented

For us, sustainability applies to all our operations. This is why we have invested in ensuring quality and sustainability throughout our operations. It is why we certify our operations as widely as possible and have done since 2006. Our company is certified according to:

- ISO 9001 Quality System

- ISO 14001 Environmental Management System

- ISO 22000 (HACCP) Food Industry Management System

- ISO 45001 Employees Occupational Health and Safety System

Safe process, products and services

We deliver our products to more than 50 countries every year. Each consumer opens and enjoys the contents of a bottle sealed with one of our bottle caps. This is why we pay special attention to the food safety of our products, especially in the end use of the products, and also during their manufacture. Our bottle caps are manufactured in Finland by Finn-Korkki’s professional work community. We monitor our work, and it is also monitored by the authorities, for instance in the use, handling and storage of our chemicals. All the products we manufacture are BPA-free.

- Our products and their manufacture comply with EU food safety regulations. We regularly train in the implementation of safety, based on the latest available research from the authorities and follow the latest legal developments.

- We work closely with material suppliers to provide the most up-to-date information on the safe use of materials in production and in our products.

- All products we manufacture are BPA-free, to ensure that our products are safe to use.

- When possible, our caps have printed instructions on them to ensure our products are used correctly.

- We pay attention to occupational safety and ergonomics during training and equipment procurement.

- Our operations have been audited according to the ISO 45001 Occupational Health and Safety System and the ISO 22000 (HACCP) Food Industry Management System.

Clean climate

We have investigated the impacts of our own activities on the climate and the environment. The carbon footprint of our own operations is currently 520 tonnes of CO2 emissions. We know that the biggest impacts are currently from the production of the raw materials we use, from emissions due to the use of natural gas in our production and from the logistics in our supply chain. As a result, our aims are to reduce the use of natural gas in our own production and minimise climate emissions from transport in cooperation with our logistics partners.

- Our goal is to be completely carbon neutral by 2035.

- Our carbon footprint in 2024 was approximately 520 tonnes of CO2 emissions (per scope1 and 2 of the GHG protocol).

- In 2023 solar panels were installed on the factory roofs, in total 800 panels with a 325 kWp rating.

- We recognize that our biggest source of emissions is from the use of natural gas in our production.

- We ensure that emissions are minimised by afterburning the gas produced until there are almost no volatile organic compound (VOC) emissions.

- We have decided to study modernisation of our existing printing line oven that can significantly decrease the use of energy compared to the current oven. This work is still ongoing.

- Our electrical energy is 100% from fossil-free sources of which 41.4% is from renewable sources. Of our heating energy 90% is from renewable sources. The target for district heating energy is to use 100% renewable sources by 2030.

- Our operations have been audited in accordance with the ISO 14001 Environmental Management System since 2006.

Employee well-being

Our aim and our commitment is to create a good workplace and work community for our employees. We understand that developing our operations and achieving our sustainability goals requires the active involvement and commitment of our personnel. This is why we are increasing the importance of well-being, health and safety in our operations. Our organisation is small and has a low hierarchy. The owners are actively involved in day-to-day activities, which enables good employee relations.

- We provide our staff with expanded occupational health care to ensure their well-being and ability to work.

- Our operations have been audited in accordance with the ISO 45001 Occupational Health and Safety System since 2006.

- We support the well-being of our personnel by paying half the cost of after work activities that promote physical exercise.

- We support the occupational safety and well-being of our production personnel with, for example, training and by investing in and paying attention to workplace ergonomics.

We support the UN Sustainable Development Goals

Our actions contributes to all 17 UN Sustainable Development Goals. At this time, we have chosen four objectives that we can best promote:

Finn-Korkki have been awarded the Silver Ecovadis rating for 2025.

|  |  |