Historien bakom rivkapsyler

Historien om Finn-Korkki Oys affärsverksamhet går tillbaka till år 1868. Företaget tillverkade då som nu flaskkapsyler och förslutningsutrustning. De första produkterna var naturkorkar för flaskförslutning.

Historien om Finn-Korkki Oys affärsverksamhet går tillbaka till år 1868. Företaget tillverkade då som nu flaskkapsyler och förslutningsutrustning. De första produkterna var naturkorkar för flaskförslutning.

August Wicander, 1836-1891 (se bild), blev en välkänd industriman under 1800-talets senare del. Hans affärsintressen låg i korkprodukter, men han ägde också ett rederi. Verksamheten berörde många länder i och utanför Europa.

August Wicanders son Hjalmar Wicander, 1860-1939, och hans sonson Carl August Wicander, född 1885, fortsatte familjens industriella traditioner i tre generationer.

Wicanders tillverkade naturkorkar för flaskförslutning

1871 grundade Wicander Åbo Korkfabrik som skulle tillverka naturkorkar för flaskförslutning i Åbo, Finland. Bilden visar Ab Wicanders & Larssons fabrik som byggdes i Åbo 1893.

1871 grundade Wicander Åbo Korkfabrik som skulle tillverka naturkorkar för flaskförslutning i Åbo, Finland. Bilden visar Ab Wicanders & Larssons fabrik som byggdes i Åbo 1893.

Under de kommande 60 åren öppnades fabriker, kontor och lager över hela Europa och Ryssland. Företaget köpte korkodlingar och övertog ett konkurrerande företag i Portugal. De ryska och polska företagen nationaliserades 1917 respektive 1945.

Rivkapsylen ALKA

Under 1930-talet utvecklade Wicanders aluminiumkapsylen ”ALKA” och började tillverka den. Det var en rivkapsyl, även kallad ripcap, med en korktätning. Flaskorna på bilden är förslutna med kapsyler av typen ”ALKA”.

Under 1930-talet utvecklade Wicanders aluminiumkapsylen ”ALKA” och började tillverka den. Det var en rivkapsyl, även kallad ripcap, med en korktätning. Flaskorna på bilden är förslutna med kapsyler av typen ”ALKA”.

Vid denna tid drev August Wicander Korkfabriker (AWK) fyra fabriker i Finland, nämligen Wicander & Larsson, Plyyshi & Matto Ab, Turun Korkkitehdas och Drumsö Korkfabrik.

Fabrikerna lades ned under 1960-talet då verksamheten överfördes till Oy Wicanders Ab. Det företaget satsade främst på korkgolv och naturkorkar.

Tillverkare av MaxiCap-kapsyler

Det som följde var en innovationsperiod med utvecklingen av de första förtillverkade ”lättöppnade” kapsylerna på 1970-talet.

Det som följde var en innovationsperiod med utvecklingen av de första förtillverkade ”lättöppnade” kapsylerna på 1970-talet.

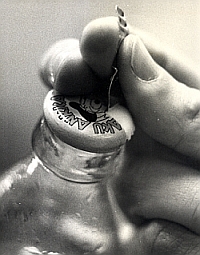

Denna kapsyl, känd som ”MaxiCap”, tillverkades av aluminium i ett stycke, med en tätning av plast. Kapsylerna försågs med inpräglade skåror under tillverkningen, vilket gjorde dem enkla att öppna. Bilden visar den veckade öppningsfliken som gjorde ”MaxiCap” enkel att öppna.

1979 öppnade Wicanders Finn-Korkki-fabriken i Tavastehus för att tillverka ”MaxiCap”-kapsyler och traditionella kronkorkar.

RingCrown – Ringkapsylen

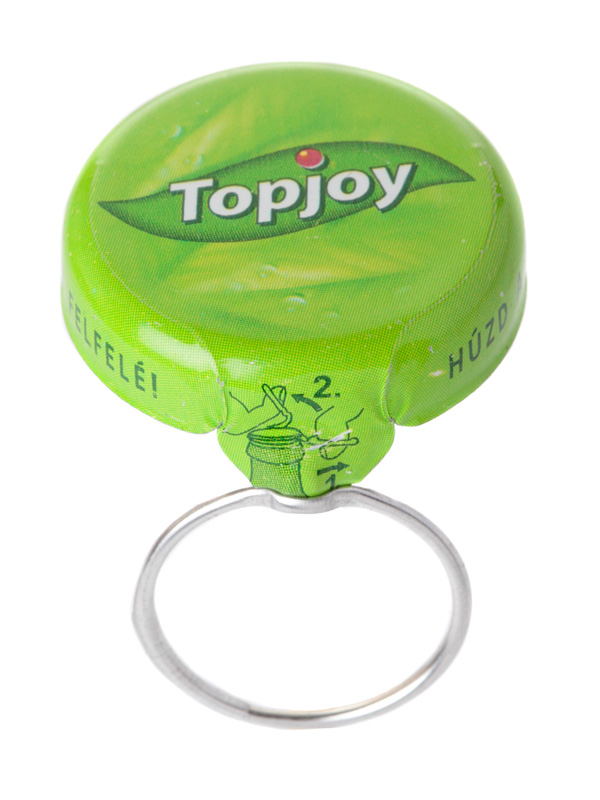

Finn-Korkki Wicanders utvecklade ringkapsylen RingCrown – då kallad MaxiCrown, i början av 1980-talet. Ringkapsylen var utförd helt i stål och i två delar. Denna lösning utnyttjade råmaterialet effektivt, så att produktionsspill och kostnader minimerades.

Rivkapsylen RingCrown kallades ursprungligen kallades MaxiCrown.Finn-Korkki började tillverka RingCrown-kapsyler 1984. I januari 1989 köpte Finn-Korkki Oys ledning ut verksamheten från Wicanders och blev ett självständigt bolag.

Rivkapsylen RingCrown kallades ursprungligen kallades MaxiCrown.Finn-Korkki började tillverka RingCrown-kapsyler 1984. I januari 1989 köpte Finn-Korkki Oys ledning ut verksamheten från Wicanders och blev ett självständigt bolag.

De nya ägarna började producera värmeljuskoppar 1989 och ljuslyktor 1992. Kundservicen blev mer flexibel 1998 då Tavastehus Grafipalvelu Oy köptes in, och gav fördelen att ha en intern presstjänst.

Finn-Korkki Oy hade såväl ambition som förmåga att förnya sig. Detta ledde till att man år 2000 utvecklade och började tillverka flaskförslutningar för Absolut Vodka.

RingCrown ersatte MaxiCrown 2001 och blev det registrerade varumärket för Finn-Korkkis ringkapsyl. Produktnamnet RingCrown beskriver perfekt vad kapsylen är – en kronkork med en ring för enkel öppning.